3D scans & virtual tours reduce costly site visits for utility

SITUATION

Wastewater Utility Improves Efficiency & Reduces Costs With 3D Scans

One of the largest wastewater and stormwater containment facilities in North America serves over four million customers. As a private/public entity, the CSO (combined sewage overflow) facilities are accountable for the value they bring to the communities and cities they serve in the entire metropolitan area. With 3D scanners and Matterport technology, virtual access and tours delivered invaluable insights in the life cycle of this stormwater facility and enabled a new level of external vendor management.

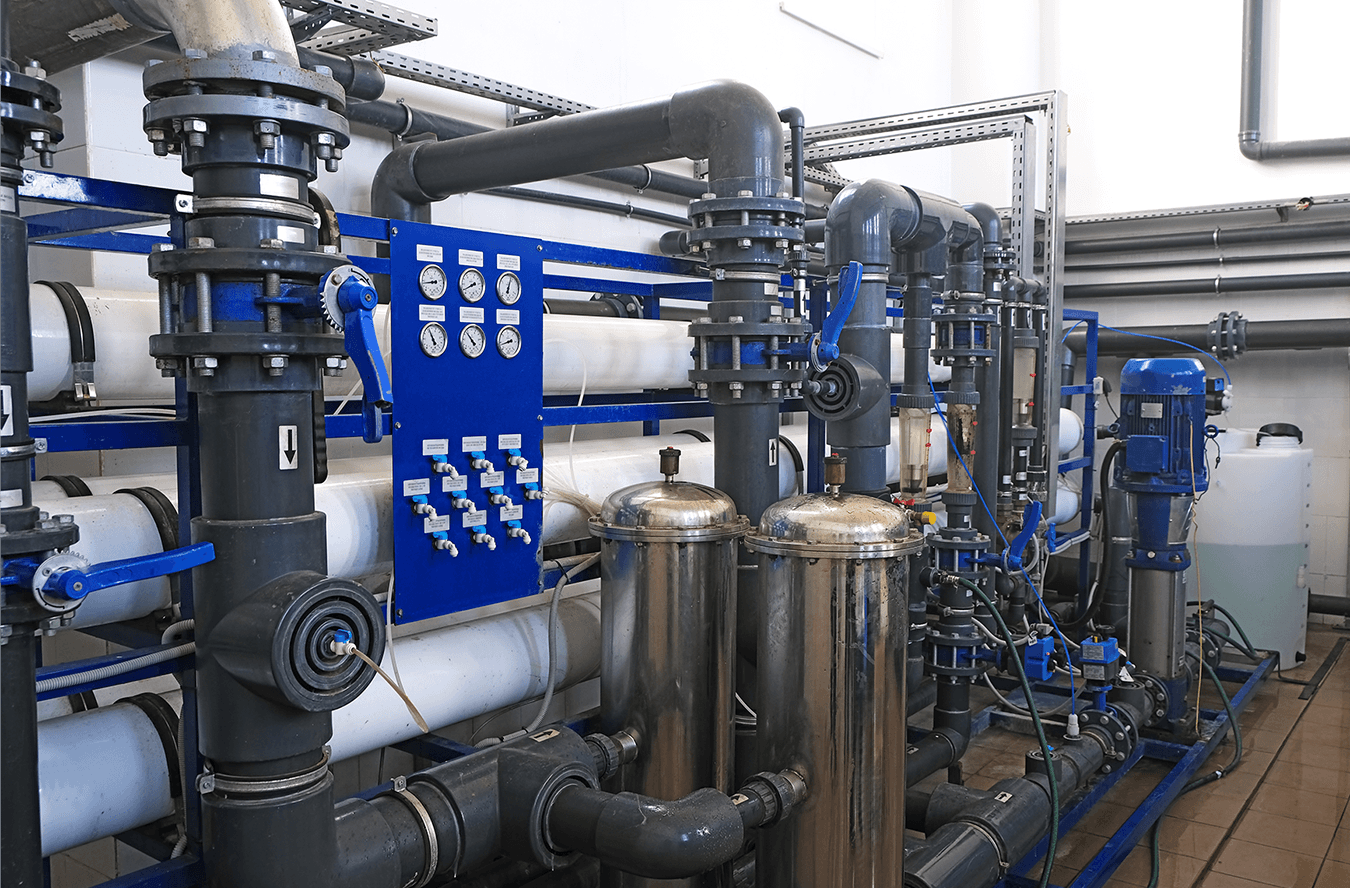

The high security utility holds giant containment systems covering over three million square feet. Thousands of acres hold reservoirs, tanks, chambers and pipelines where wastewater is stored, moved, separated, processed and filtered. Massive storage areas above the ground hold and move water, while underground chambers and pipelines collect stormwater and sewage for processing.

CHALLENGE

Constant maintenance and services are needed throughout the facilities for repairing and maintaining pumps and systems. Protocols for vendor access to visit sites to gather information for bids was costly and time consuming. In the past, a facility would need to be shut down and cleaned prior to vendor walk throughs for a small team to measure, photograph and gather details in a short window. This process cost hundreds of thousands of dollars and diverted resources and manpower away from the primary goal of running the facilities.

When the vendor bids came in, additional fees and costs were added due to the limited access and unknowns.

SOLUTION

The utility managers needed a way to grant access for select vendors to virtually to walk through the CSO with their entire team. The VTS 360Pro team determined that two types of capture technology were needed to accommodate the range of vendors that needed access. Engineering firms required detail data of the above and underground facilities with precision dimensions and measurements. The details, including pipe fitting distance, pump systems and clearances, needed to be within millimeters of accuracy. Multiple technologies were required including 3D scanners, drones and lidar scanners. The data was delivered in ReCap®, an Autodesk® format widely used by Engineering firms.

Other vendors didn’t require the engineering detail but needed to see the spaces, dimensions and access points. For example, high powered pressure washers are needed to clean chambers. Using the Matterport camera system, VTS 360Pro crews created a cloud based immersive 360 tour that allowed for virtual walk throughs of the chambers and facilities.

In the process of capturing, the VTS 360Pro crews experienced firsthand the manpower constraints and restrictions with security, cleaning and preparation involved to get the capture crews in and out of the facilities. Storms and floods delayed scanning several times and they had to be prepared for challenging conditions.

“Until you’ve been in these facilities, it is difficult to comprehend the complexity and scale. Lidar, terrestrial scanners and 3D Matterport cameras were used. There was an aerial component using drones. It was like climbing a massive mountain, with milestones that changed constantly.”

The most complex part of the project was after the scanning. The entire team was involved in the detailed process of organizing the data, scans and files, and combining into easy to manage data sets in the ReCap® and Matterport virtual tour format.

WIN

The results go far beyond the typical 3D laser scanning applications for engineering and construction. Digital documentation and access provided a high level of value inside the life cycle of this stormwater facility and enabled a new level of external vendor management. The data was used internally to update asset inventory records and identify chambers and areas that needed attention. Design and construction firms use it for clash detection, design, simulations and installation planning without interfering with day-to-day operations.

Engineers and project managers can see and measure the underground pipelines and 3D points of the corridors and sub chambers. It shows power lines, poles, pipes and trees. With 3D pipe views, clearances around the pipe from multiple angles can be seen and measured.

The 3D models and the Matterport virtual tour avoided hundreds of thousands of dollars in shutdowns when vendors needed site access to create bids. Utility managers could grant access to vendors during the process to walk through the facilities virtually with their entire teams. These improvements improved security, reduced risk and enabled the facility to deploy resources and manpower more efficiently.

In addition to the thousands of dollars saved, vendor bids were more accurate.

“Turning to 3D scanning professionals with expertise of large-scale projects paid off for this client. It was a complex project combining the data from different technologies, but the resulting model and tours were easy to access and use.”